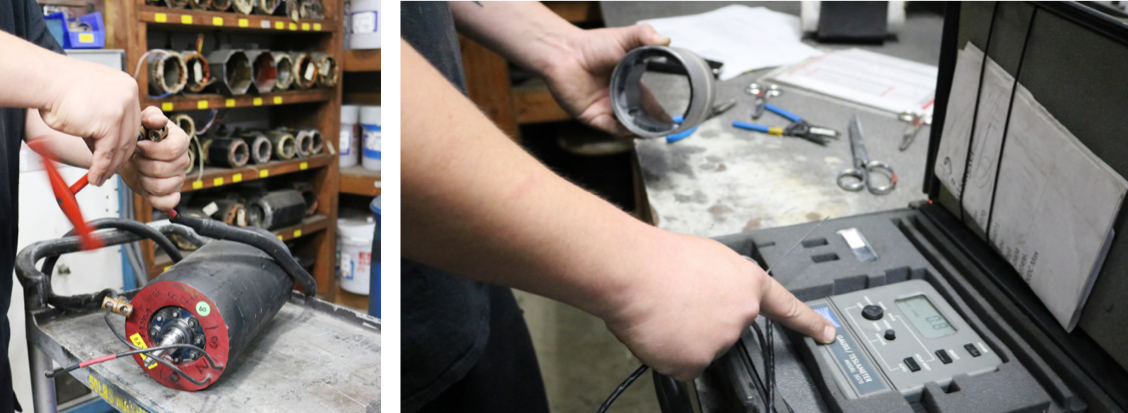

Winding

While many OEMs and other repair shops would consider a bad stator winding not repairable, Servotech goes the extra mile to rewind them. It’s not always an easy task, but it can be the difference in waiting just days versus months to get your machine running again.

Machining

Our in-house machine shop adds enormous value to the work we do. Rather than relying on a third party for machine work, we have our own team of talented machinists on-site. In addition to our manual machine shop, we have the capability to fabricate parts with our CNC machining center and lathe.

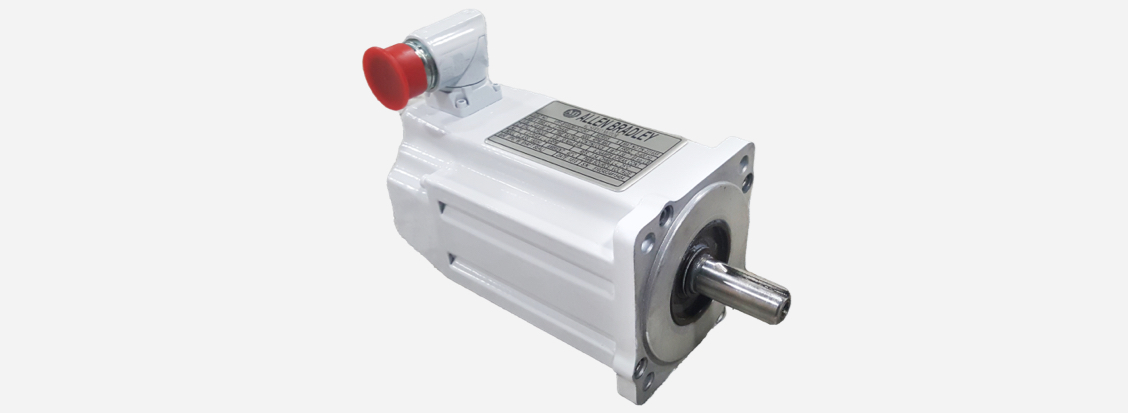

Services for Food-Grade Motors

Motors used in food production require special treatment to make sure they can withstand the harsh environments they are used in. This includes:

- Installing new Viton and Teflon seals

- Stainless steel hardware used throughout

- Food-grade epoxy paint

- Special food-grade grease used in bearings and actuator screws

Magnetizing

Magnetizing is a specialty that Servotech has perfected over the years, and we have a growing inventory of charge fixtures we’ve made. When possible, rotor magnets can be brought back to life by being recharged with our capacitor discharge magnetizer.

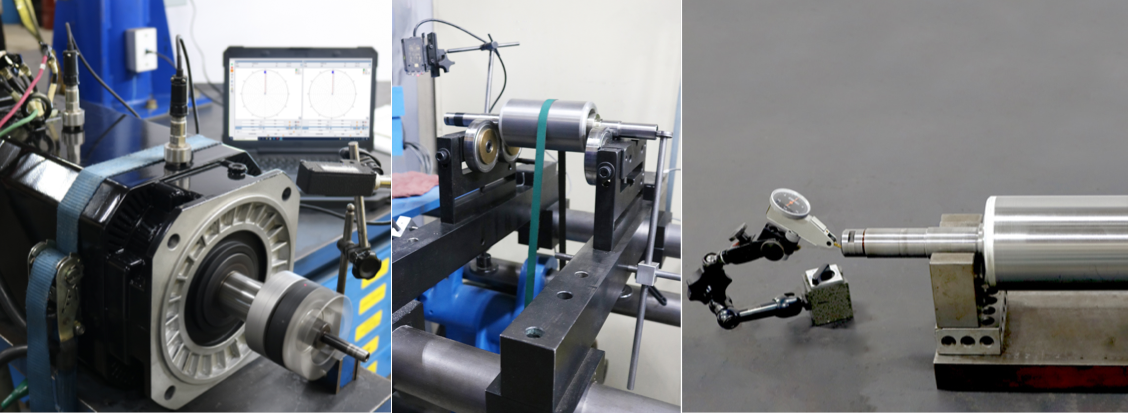

Balancing & Vibration Testing

All rotors and armatures that go through machine repair must get balanced. All spindle rotors get balanced before assembly, and once in final test, all spindle motors undergo vibration analysis to ensure smooth running and long bearing life.