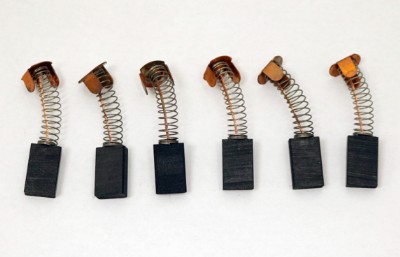

Replacement Brush Kits

We stock over 500 types of brushes, brush caps, brush holders and complete end cap assemblies. If we don’t stock it, we can manufacture it within 24 hours.

Featured Brushes:

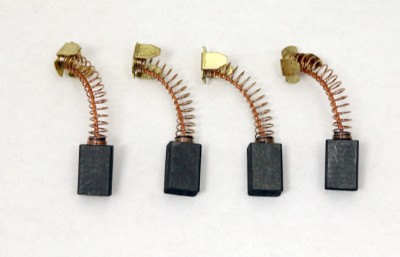

- Glentek GM6000, Glentek GM5060, Fadal MTR-0010 Replacement Brush Kit$78.76

- GM4040, GM4050, Fadal MTR 0002, MTR 0003, MTR 0007, Glentek GM4020 Replacement Brush Kit$64.04

- SEM MT30, CMT MT30, Motion Control MT30, Anilam 37000117 Replacement Brush Kit$62.68

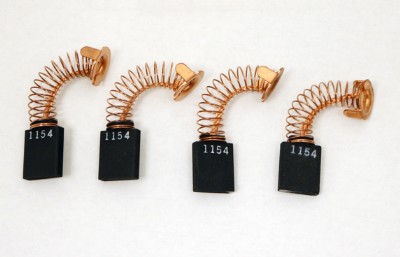

- SEM MT40 Replacement Brush Kit$77.40

- Fanuc 5M, 6L | Gould M237 | Yaskawa UGJMED-60 Replacement Brush Kit$66.88

- Fanuc 10m, 20m, 30m Replacement Brush Kit$65.00