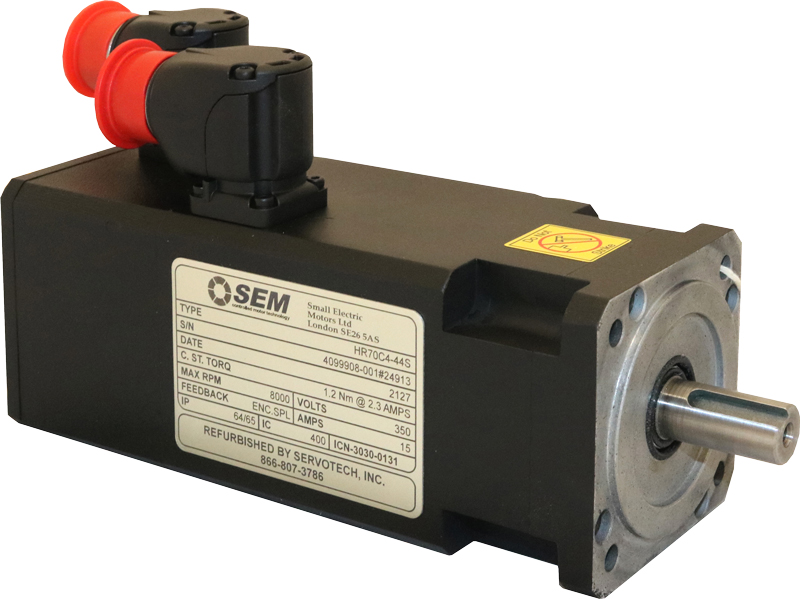

SEM AC Servo Motor Repair

When you send your SEM AC servo motor to Servotech, you can trust that it is in good hands. Our technicians have decades of experience working with these motors, as we were once North America’s warranty center for SEM until they closed their facility in the U.K.

Since SEM no longer manufactures AC servo motors, sourcing replacement parts or even replacement motors can pose a challenge. Our team takes pride in stocking a massive inventory of obsolete parts such as specialty connectors that these motors often use. If there is a part that can no longer be purchased, we will find a way to manufacture it ourselves or come up with a compatible replacement.

SEM AC servo motors can utilize a variety of feedback devices, such as encoders and resolvers. Regardless of what type of feedback your motor has, we will be able to properly test it and repair or replace it if necessary. Many of these feedback devices come from overseas and can take weeks or months from the factory. For this reason, we keep an inventory of encoders and resolvers commonly seen on SEM servo motors. This allows us to refurbish your motor in record breaking time, minimizing downtime for our customers.

We take pride in offering you the highest quality refurbishment with a delivery time you can count on. Between our vast inventory of obsolete parts and the amount of wisdom and skill our team possesses, Servotech is clearly the most qualified choice to repair your SEM AC servo motor.

SEM DC Servo Motor Repair

SEM DC servo motors are nothing new to our technicians. These motors endure an extensive evaluation once they arrive, and all electrical and mechanical components of the motor are carefully inspected. We not only identify the cause of failure, but we check for any worn parts that could lead to issues in the future. Treating the motor as a whole rather than fixing what is broken extends the lifespan of your motor, keeping you up and running longer.

SEM DC servo motors also contain brushes, which are made of carbon. These brushes will wear over time, causing contamination throughout the motor. When you send your motor to Servotech, we will clean it thoroughly before installing brand new brushes. We also stock hundreds of brushes of various sizes and styles (check out our online store for replacement brush kits!) to minimize turnaround time on your repair.

When you send your SEM DC motor to Servotech to be refurbished, you can trust that your motor is in good hands. We are proud to service these motors and offer the highest quality, quickest refurbishment in the industry.

Our Repair & Refurbishment Process

1. Checking In

- Motor is photographed and documented by our receiving department

- Unique job number is assigned

- Acknowledgement is sent via email

- Motor is delivered to the appropriate department to be evaluated

2. Evaluation

The evaluation of each SEM servo motor is extremely thorough and is 100% free for all our customers. Our technicians fully inspect all mechanical and electrical parts. They also perform multiple tests to determine the cause of failure. This includes, but is not limited to:

- Bearing fits

- Housing fits

- Worn output shafts

- Corroded and/or broken flanges

- Burnt Stator Windings

- Failed Encoders

- Damaged Connectors

3. Quote

Our purchasing department then generates a firm quote, outlining the cause for failure, and listing all needed parts for repair. Our team excels in sourcing any parts that are not already stocked in our extensive inventory. We understand that getting your machine up and running is of utmost importance, and we go above and beyond to offer you the quickest delivery possible.

4. Servo Motor Repair

Once the quote is approved, orders are placed for any needed parts and our technicians proceed with repairs. Anything that requires our in-house services, such as winding or machine work, is taken to the corresponding department. When ready, the motor is re-assembled with all new parts and hardware, bringing it to good-as-new condition.

5. Final Testing

Upon completion of repairs, the SEM servo motor heads to our quality control department for final testing. Here, we review the entire repair and run it on a factory specific drive. Using the same drive that is used in your machine ensures that your SEM motor will run just as it should once re-installed. We take great pride in maintaining an inventory of factory drives as it allows us to offer the most effective, reliable refurbishment possible.

6. Painting & Re-Labeling

Not only does a fresh coat of paint make your SEM servo motor look brand new, but it also provides protection from outside contaminants, extending the overall lifespan of the motor. Our painting department provides application-specific paint, such as:

- Food grade epoxy

- IP67 epoxy

- Marine epoxy

7. Return Shipping

Our shipping department takes pride in offering the highest quality care when preparing a refurbished motor for its journey back to you. Protective caps are put on connectors, nameplates are applied to the motor, and documentation is reviewed to make sure any accessories, such as eye bolts or shaft keys, are returned to you. Our high-quality spray foam packaging system creates a mold around the motor to keep it safe in the box during shipping. For larger motors that require freight shipping, we build a custom crate on-site to fit each motor’s unique size and shape..

- Bearing fits

- Housing fits

- Worn output shafts

- Corroded and/or broken flanges