Siemens AC Motors Siemens DC Motors Siemens Spindle Motors

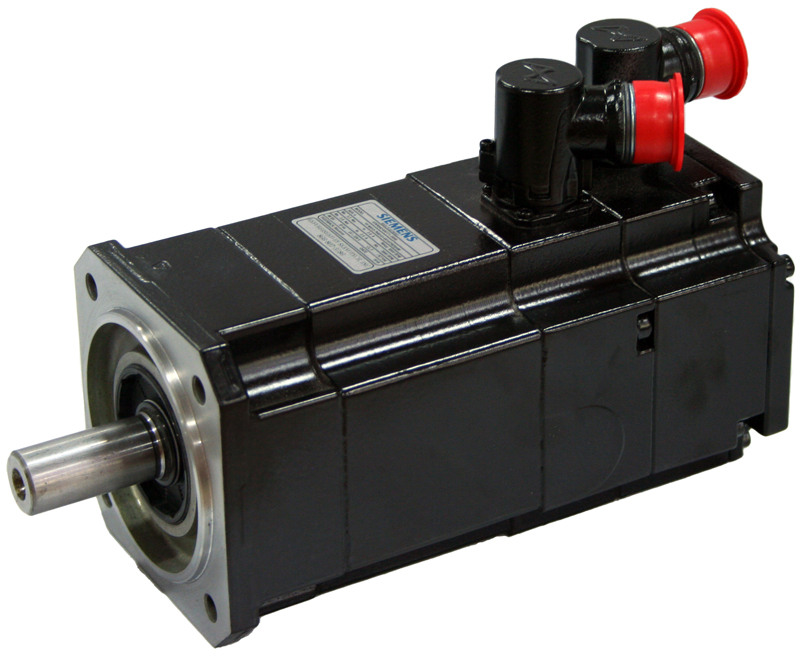

Siemens AC Servo Motor Repair

Siemens AC servo motors that arrive at our facility undergo a thorough evaluation to identify the cause of failure. The repair process will bring your broken down Siemens servo motor back up to factory specifications, just as if you bought a new one.

Most Siemens AC servo motors use encoders made by Heidenhain. Our strong relationship with Heidenhain means we have access to these parts as well as important technical documentation that can be critical to repairing a motor properly. Maintaining a large inventory of Heidenhain encoders means we don’t typically need to wait to order a new one for each job – it’s already on our shelf. When a certain encoder is not available, we can even go as far as modifying the rotor and endbell in order to use an encoder that is otherwise electrically compatible.

Older-style Siemens AC servo motors often have feedback hall sensors. While the manufacturer would deem a motor unrepairable due to broken hall sensor brackets, Servotech has reverse engineered and manufactured these brackets, allowing us to refurbish your servo motor when others cannot. This is just one example of how Servotech will go the extra mile to keep your motor up and running.

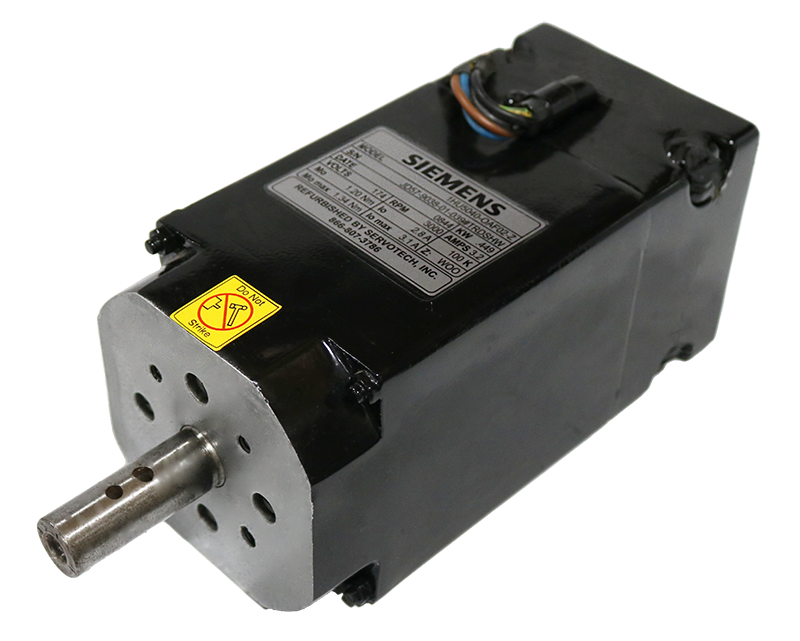

Siemens DC Servo Motor Repair

Although Siemens DC servo motors are no longer used in CNC equipment, there are plenty of them still in use today. Servotech takes pride in offering the absolute highest quality refurbishments on these motors to extend their life span and keep your machine up and running. When you send in your Siemens DC servo motor to us, you can expect it to look and function as if it were brand new once you get it back.

DC servo motors contain carbon brushes which wear down over time. While replacing the worn brushes may be a quick fix, there is still a build up of carbon contamination inside the motor. Our technicians thoroughly clean all the components of each DC servo motor to prevent this contamination from causing premature failure.

Servotech has all the needed skills and equipment to refurbish Siemens DC servo motors regardless of how it failed. We have the capability to rewind armatures and tachs, reverse-engineer outdated feedback devices, and fabricate parts in our machine shop. Our in-house services combined with an extensive inventory of hard to find parts means you can count on Servotech to properly refurbish your DC servo motor and keep your machine up and running.